|

Features and benefits |

Oil, transmission and hydraulic, Hy-Gard,, PEMO additive, and Noice Reducing Tractor Hydraulic Fluid

|

Hy-Gard® transmission and hydraulic oil |

|

Index |

|

· Product information: - Hy-Gard · Test results Hy-Gard: · Noice Reducing Tractor Hydraulic Fluid · Plus-50 II ™ and Hy-Gard Oils Price Comparison Worksheet

Dealers Only |

Features and benefits· Performance-tested both in lab and in field and approved by John Deere engineers to meet increased demands for performance and protection of transmissions and hydraulic oils. · A polymeric viscosity improver helps Hy-Gard retain its proper viscosity over a wide range of operating temperatures. For Hy-Gard to work efficiently, it must flow readily through any part of the system. Oil that is too light can cause increased wear; too heavy will cause sluggish operation and lower mechanical efficiency. · Reduces wet-brake chatter, assures high braking capacity. · Superior wet-clutch performance smoothes clutch operation. · High tolerance to water contamination without sludge formation, which could cause filter clogging and hydraulic system malfunction –anti-oxidation capability allows oil to work properly at high temperatures, helping keep transmissions and hydraulic system moving parts clean. · Provides protection against rust and corrosion, particularly during low-use periods. · Anti-wear additives keep gear and bearing wear to a minimum – extreme pressure film in Hy-Gard helps prevent metal-to-metal contact. |

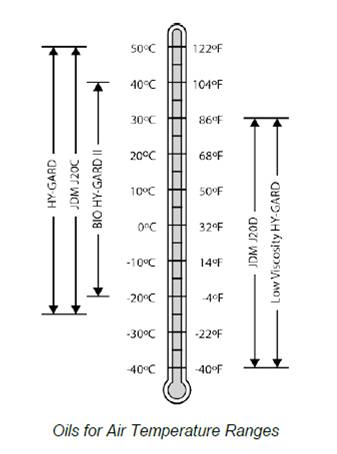

FunctionsBecause transmission and hydraulic oil must perform many different tasks at the same time, there is very little margin for error. To understand the complexity of transmission/hydraulic oil, let’s review its functions: · Prevents wear of high-torque, heavy-loaded gears and bearings. · Provides wear and corrosion protection for hydraulic pump. · Provides proper friction for wet brakes to give maximum stopping performance with minimum chatter. · Provides proper friction for clutches to engage and absorb shock loads without excessive slipping or abrupt shifts. · Provides proper friction for brakes to ensure low chatter, long life, and high capacity. · Withstands extreme pressures in hydraulic system without breaking down. · Prevents the formation of deposits on all internal parts. · Prevents foam and water damage to all internal parts. · Hy-Gard oil can be used in most applications calling for 10W-30 or 5W-30 engine oil for transmission and hydraulic oils. Note: Hy-Gard should be used in all applications calling for JDM J20C. · Low-Viscosity Hy-Gard should be used in all applications calling for JDM J20D. · Low-Viscosity Hy-Gard and Hy-Gard are compatible with hydrostatic oil and can be added to systems that contain hydrostatic oil.

John Deere does not monitor competitive or “will-fit” oils. While claiming to meet John Deere requirements, it is possible that the competitive or “will-fit” oils do not meet even the minimum performance requirements for John Deere machines, which could result in premature failures. Note: An industry classification for hydraulic/transmission oil does not exist. Each manufacturer establishes a minimum requirement that oils should meet for use in their equipment. John Deere has established a JDM J20 specification for minimum tractor performance hydraulic fluid. John Deere Hy-Gard and John Deere Low-Viscosity Hy-Gard exceed the performance of their JDM-J20 specification counterparts. The performance requirements for Hy-Gard are higher and many more performance tests are mandatory. |

|

|

|

Note: For commercial and consumer applications, the temperature range for Hy-Gard is -13°F (-25°C) to 122°F (50°C) and Low-Viscosity Hy-Gard is -40°F (-40°C) to 86°F (30°C). Check the operator’s manual for specific applications. Some applications are restricted in this temperature range. |

Chemical and physical properties: Hy-Gard |

|||||

|

Units |

ASTM |

Hy-Gard |

|||

|

Hy-Gard |

Low-Viscosity Hy-Gard |

||||

|

Viscosity |

mm2/s (cSt) |

D-445 |

|

|

|

|

|

40 degrees C |

|

|

59 |

33 |

|

|

100 degrees C |

|

|

9.4 |

7.1 |

|

Pour Point |

degrees C |

|

-40 |

-51 |

|

|

Flash point (min.) |

degrees C |

|

227 |

180 |

|

|

Total base no. |

mg KOH/g |

|

11 |

13 |

|

|

Viscosity index |

- |

|

140 |

195 |

|

|

PMB10099 Competitive oil

tested to meet |

|

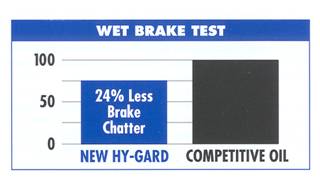

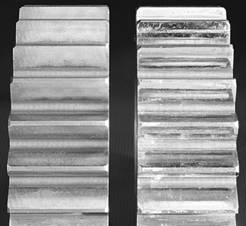

Hy-Gard has been formulated to ensure wet brakes have high braking capacity with minimum brake chatter. Three elements are considered in the wet brake test: · Braking capacity – the ability of the brake system to absorb energy – measured in torque. · Torque variation – the ability of the brake system to maintain smooth frictional operation without vibration or brake chatter. · Wear – low wear to ensure long life. Feature:Hy–Gard Oil is formulated to maximize brake capacity with minimum brake chatter and wear. Advantage:This formula provides 24-percent better brake chatter control than competitive oil. Benefit:Better brake chatter control provides smooth stopping, reduced damage from vibration, less noise, and longer brake life. |

|

PMB10100 Competitive oil tested to meet John Deere’s current JDM J20 specifications. |

|

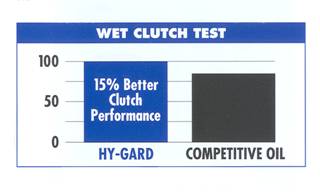

Three elements are compared in the wet clutch test: · The ability of the clutch to provide smooth engagement under maximum load. · The ability of the clutch to resist slippage. · The ability of the clutch to resist wear. Feature:Hy–Gard’s friction modifiers provide smooth clutch engagement. Advantage:The smooth clutch engagement provides 15-percent better clutch performance than competitive oils. Benefit:Better clutch performance provides longer clutch life with reduced maintenance costs. (Hy-Gard allows limited clutch slippage for smooth engagement, which reduces clutch wear and provides long life. Too little clutch slippage results in rough, jerky engagement while too much slippage can cause clutch surfaces to burn or glaze). |

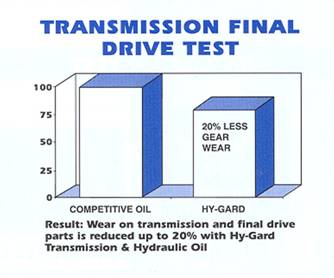

Oil gear testResult: Wear on transmission and final drive parts are reduced up to 20-percent with Hy-Gard Transmission and Hydraulic Oil. |

|

PMB10101 Competitive oil tested to meet John Deere’s current JDM J20 specifications. |

|

The anti-wear extreme pressure additives play a vital role in keeping gear and bearing wear to a minimum. Oil without these additives lacks the qualities to properly lubricate transmission parts. The JDQ95 spiral bevel/final drive gear test measures a fluid’s ability to prevent destructive wear of gear contact surfaces. Feature:Hy–Gard contains superior anti-wear additives. Advantage:These additives provide up to 20-percent less gear wear. Benefit:Less gear wear extends component life and reduces downtime. |

|

PMB10132 |

|

|

John Deere |

Competitive |

|

PMB10133 |

|

|

John Deere |

Competitive |

Order information |

|||

|

Part |

|

|

Pkg. |

|

U.S. |

|||

|

TY6354 |

Hy-Gard oil |

1 gal. |

6 |

|

TY22062 |

Hy-Gard oil |

2-1/2 gal. |

2 |

|

AR69444 |

Hy-Gard oil |

5 gal. |

1 |

|

TY6238 |

Hy-Gard oil |

30 gal. |

1 |

|

AR69445 |

Hy-Gard oil |

55 gal. |

1 |

|

TY26992* |

Hy-Gard oil |

275 gal. |

1 |

|

TY22035 |

Low viscosity Hy-Gard |

1 qt. |

12 |

|

TY22000 |

Low viscosity Hy-Gard |

1 gal. |

6 |

|

TY6342 |

Low viscosity Hy-Gard |

5 gal. |

1 |

|

TY6344 |

Low viscosity Hy-Gard |

55 gal. |

1 |

|

* Truckload orders only |

|||

|

Canada |

|||

|

TY26975 |

Hy-Gard oil |

3.78 L |

12 |

|

TY22062 |

Hy-Gard oil |

9.5 L |

2 |

|

AR69444 |

Hy-Gard oil |

18.9 L |

1 |

|

TY22090 |

Hy-Gard oil |

125 L drum |

1 |

|

TY27323 |

Hy-Gard oil |

1000 L |

1 |

|

TY22035 |

Low viscosity Hy-Gard |

946 L |

12 |

|

TY22086 |

Low viscosity Hy-Gard |

10 L jug |

2 |

|

TY6342 |

Low viscosity Hy-Gard |

18.9 L |

1 |

|

TY6274 |

Low viscosity Hy-Gard |

205 L drum |

1 |

|

TY27324 |

Low viscosity Hy-Gard |

1000 L |

1 |

|

Warranty: 90 days |

|||

Features and benefits· Formulated with canola oil which allows grass and soil to regenerate quicker after spills or leaks with NO residual effects on the environment, such as contamination to soil and groundwater. · Canola oil composition reduces friction and wear. · Improved oxidation resistance allows machines to operate n hotter temperatures. · Fulfills all JDM J2OC requirements. · Meet or exceed performance standards and environmental requirements. · Cold-start performance: -13o F to 122o F (-25o C to 50o C). · 100% compatible with petroleum oils. |

Environmental requirementsThis fluid meets or exceeds the environmental requirements defined by the following tests: OECD 301b Sturm fast biodegradability = 75% OECD 202 = EC50 > 100mg/L CEC L-33-A-93 biodegradability = 94% WGK rating of 1 |

Order information – Bio Hy Gard II |

|||

|

Part |

|

|

Pkg. |

|

U.S. and Canada |

|||

|

TY26252 |

Bio Hy-Gard II |

5 gal. |

1 |

|

TY22063 |

Bio Hy-Gard II |

55 gal. |

1 |

|

Warranty: 90 days |

|||

|

Note: Hy-Gard and Plus-50 II can be combined in orders using the bulk oil program. Check with your service depot for program details. |

|||

|

Machine type |

Machine model |

|

Tractor |

655, 755, 855, 955, 670, 770, 790, 870, 970, 990, 1070, 4500, 4600, 4700 |

|

Timberjack Machines |

Various |

Order information - PEMO |

|||

|

Part |

|

|

Pkg. |

|

U.S. and Canada |

|||

|

LVU11673 |

PEMO anti-chatter additive |

12 oz. |

4 |

|

Problem or situation: · · The brake disks chatter on final drive axles while applying the brake pedals to stop the tractor.

· Brake disk on final drive rattles on pinion shaft while applying the brake pedal. · The brake disk fits loose on shaft for ease of assembly.

· This problem may be the result of what is referred to as stick-slip which is the friction disk adhering to the steel plate and then breaking loose. This results in chatter in the brakes and can be noted as noise and vibration during braking. This problem could relate to an issue with the oil, such as water contamination, or it could relate to the mechanical components in the system.

Solution: · It is important to verify the cause of the noise is not due to high water content in the transmission oil. Oil sample would need to be tested. · If brake chatter is encountered, run and Oil Scan to determine if water contamination is present. If water is found, warm up the tractor, drain and replace filters, and refill with Noise Reducing THF. Run and Oil Scan to verify water is removed to an acceptable level. If the water content is okay, test the tractor to determine if the brake chatter persists. If brake chatter continues, drain and refill the tractor, retest, or in severe cases, the brake disks may require replacement. If the brake chatter issue is not resolved at this point, the oil will not resolve the problem; look for a mechanical resolution. · A new fully formulated fluid, “Noise Reducing THF”, has been developed to reduce brake chatter. In certain conditions this product will replace Hy-Gard oil in our tractors to reduce the brake noise. This fluid is suitable for use wherever JDM J20C is shown as acceptable to use. · - Noise Reducing Tractor Hydraulic Fluid, 1 gallon (3.78 L) – TY27014 - (NLA) - Noise Reducing Tractor Hydraulic Fluid, 5 gallons (18.9 L) – TY27015 - Noise Reducing Tractor Hydraulic Fluid, 55 gallons (208 L) – TY27016 – (NLA) Note: Dealers can order this fluid on Dealer Daily stock orders or Machine Down orders.

IMPORTANT: Do not add other additives to fluid. Additional information: · Brake disk may need to be changed if the oil is contaminated with moisture. · Drain oil from the complete system (brakes, MFWD when engine is running, and oil cooler). · Change transmission and hydraulic filters. · Fill with 20-25 liters of Hy-Gard oil. Start engine and activate MFWD and brakes. · Put a jumper hose in SCV and activate SCV to flush the system (10-15 minutes). · Drain oil again as described in the second step. · Change transmission and hydraulic filters again. · Fill with the correct amount of the new J20C Noise Reducing THF fluid with enhanced brake noise reduction to the system (transmission and hydraulic). · Change brake disks.

Note: If the brake chatter issue continues, the oil isn’t the solution, look for a mechanical explanation. |

Order information

|

|

|

Pkg. |

|

TY27014 – (NLA) |

Hydraulic Fluid, Noise Reducing Tractor, 1-gallon (3.78 L) |

6 |

|

TY27015 |

Hydraulic Fluid, Noise Reducing Tractor, 5-gallon (18.9 L) |

1 |

|

TY27016 – (NLA) |

Hydraulic Fluid, Noise Reducing Tractor, 55-gallon (208 L) |

1 |

Plus-50 II and Hy-Gard Oils Price Comparison WorksheetUse this worksheet to complete a competitive market analysis to help convert you from competitive oil to John Deere Plus-50 II and Hy-Gard oils. |

Plus-50 II and Hy-Gard Oils Price Comparison Worksheet

|

|||||||

|

Name: |

|

Date: |

|

||||

|

Address: |

|

|

|||||

|

|

|

|

|||||

|

|

|

|

|||||

|

Telephone No. |

|

|

|||||

|

|

|

|

|||||

|

|

|||||||

|

|

|||||||

|

John Deere |

Price per gallon |

||||||

|

One gallon |

55-gallon drum |

Bulk |

|||||

|

Plus-50 II 15W-40 engine oil |

|

|

|

||||

|

Hy-Gard Transmission fluid |

|

|

|

||||

|

Comments: |

|||||||

|

|

|||||||

|

Product: |

Price per gallon |

||||||

|

One gallon |

55-gallon drum |

Bulk |

|||||

|

15W-40 engine oil |

|

|

|

||||

|

Transmission fluid |

|

|

|

||||

|

Comments: |

|||||||

|

|

|||||||

|

Product: |

Price per gallon |

||||||

|

One gallon |

55-gallon drum |

Bulk |

|||||

|

15W-40 engine oil |

|

|

|

||||

|

Transmission fluid |

|

|

|

||||

|

Comments: |

|||||||

|

|

|||||||

|

Product: |

Price per gallon |

||||||

|

One gallon |

55-gallon drum |

Bulk |

|||||

|

15W-40 engine oil |

|

|

|

||||

|

Transmission fluid |

|

|

|

||||

|

Comments: |

|||||||

Last modified: 01Sep17.